|

Like all good things in life, a new antenna system with

a tower begins with a hole in the ground. This hole measured

3' X 3' X 5' and was dug through three layers of calichi'. Calichi

is a mexican word for "mud concrete". It is extremely

hard and very difficult to dig with any known impliment. I used

a post hole digger and a set of buckets. The system was to dig

with the post hole digger until the buckets were full. Then climb

out of the hole and carry the buckets to the back yard and dump

them. Needless to say it took me two weeks to dig the hole. Once

the hole was done, then came the Rebar and the bolts. The bolts

connect the concrete to the tower base and the rebar reinforces

the concrete. The sheet from the concrete company says the materials

to make the concrete weighed 7250 pounds before the water was

added. That tower isn't going anywhere, unassisted. |

|

|

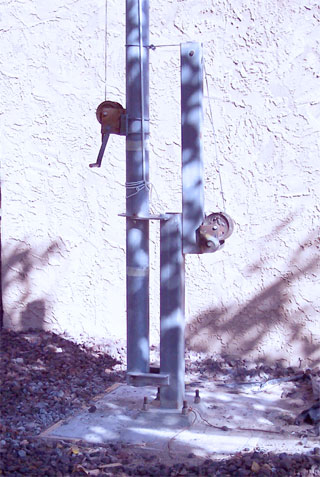

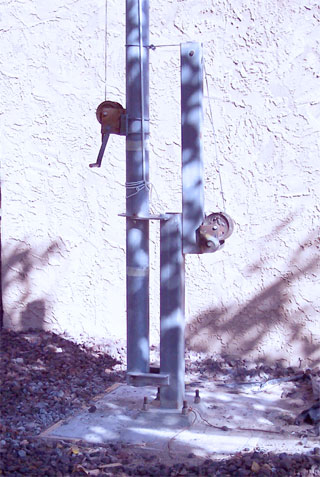

Once the hole is filled with concrete then you can attache

the base of the tower to it using the bolts that you placed in

the concrete. This is where you find out how good your measurement

skills have been. Luckily, my tower base fit perfectly on the

bolts. and the tilt over base was mounted.to the concrete. From

here on, the tower project was getting easier. The telescoping

mast was attached to the base and the cables were hooked up and

the mast section was raised to a upright position. The City inspector

was called and the tower passed it's inspection. Next came the

antennas, coax, coax arms, rechecking all the bolts were tight,

and worrying about the winches being able to lift that load.

But it all went up and up and up. The system seems to be working

as now the DX stations answer me when I call them. Now it all

seems worth while, but when I was digging that hole through the

very hard clay, I HAD MY DOUBTS. |

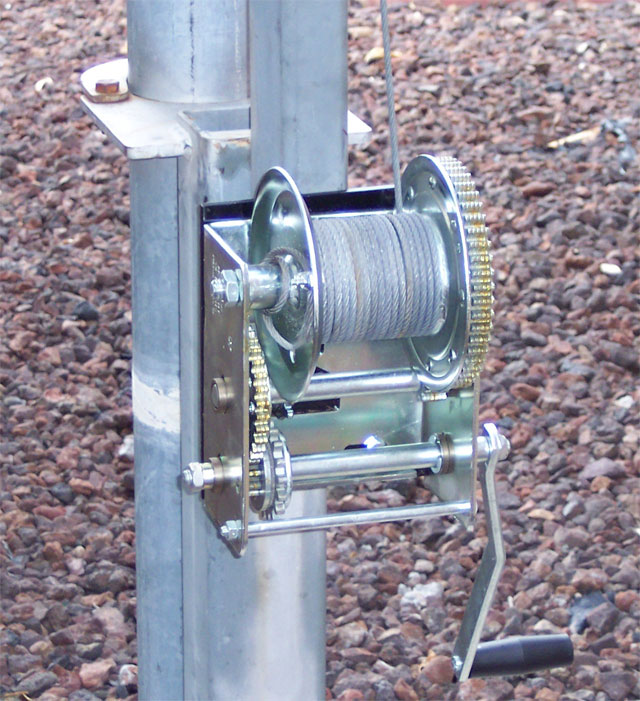

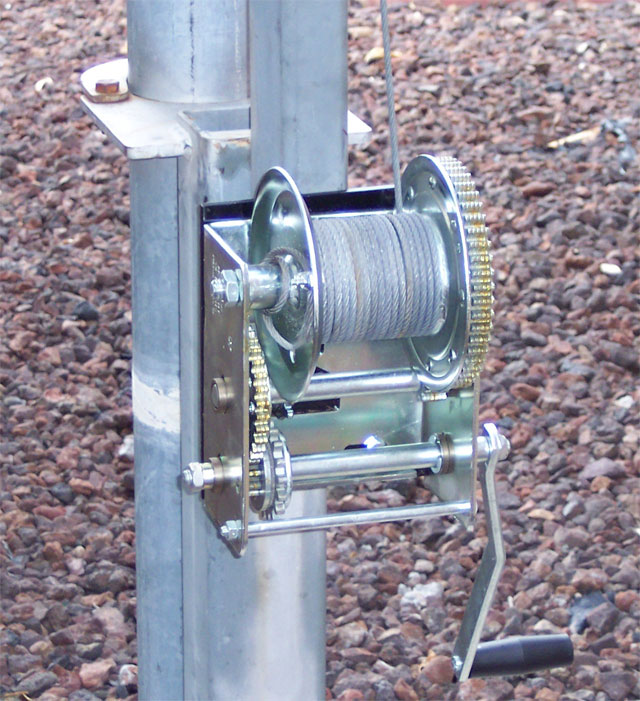

The Great Tower Modification:

A new 15:1 ratio winch for the Lay over winch

The two pictures below show the new winch installation.

|

My original lay over winch on my Wilson 40 foot tower was

a Fulton KR1000 winch. It had been installed for about 25 years

but still worked very well. The problem was that the 5:1 ratio

was getting difficult for an "old man" to crank the

tower over and back up. The modification consisted of buying

a Fulton KR2500 braking winch and install in place of the KR1000.

To provide extra support, a 1/4 inch piece of steel plate was

mounted underneath the winch and on top of the lifting arm. The

pictures below show the installation. It was the best thing I

have ever done in that laying the tower down and up is much easier

with the 15:1 ratio of the double action winch. |

|

|

|

|

|